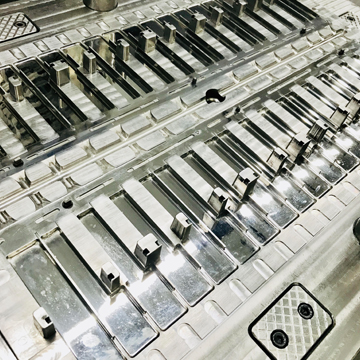

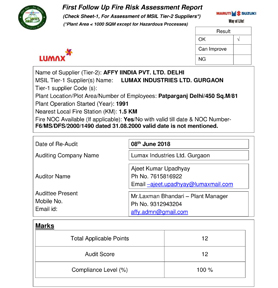

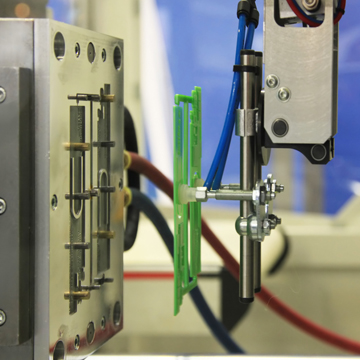

INJECTION MOLDING

Here at Affy India, we have a state-of-the-art manufacturing facility with 60 injection molding machines that range from 60 ton to 250 ton. These Japnense engineered machines offer outstanding precision, high quality, dynamic responses and the fastest dry cycle times in the industry.

Materials

We can run all types of resins from commodity to engineered grades, high temperature to filled materials.

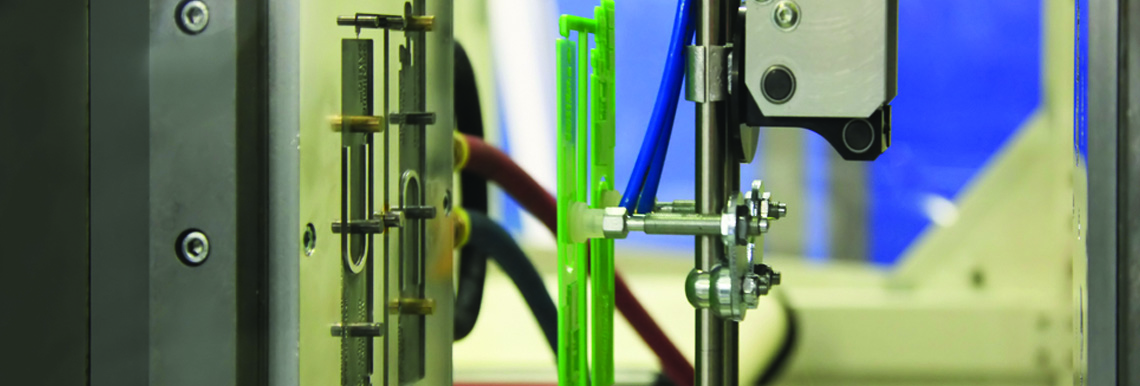

Automation

We are dedicated to improving productivity through automation. The machines are operated in an automatic mode to the greatest extent possible. The result is a reliable, efficient, and cost effective system to improve manufacturing process.

Assembly solutions

From prototyping and tooling, to finishing, assembly, and packaging, Affy does it all. Our secondary applications include: